This technology is regarded as a Technology Landmark for use in an OmegaMap. Its widespread use would contribute significantly to the effectiveness in which electricity is transmitted to moving objects such as motor vehicles that now have to be idle while recharging.

The information presented here is based on an article entitled “Researchers at Stanford have made a milestone achievement towards making Wireless Electricity Transmission a Reality”, written by Felix Omondi in innov8tivemag, on April 14, 2018.

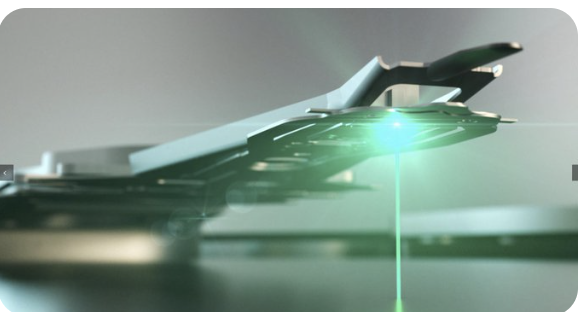

It was Nikola Tesla who pioneered the concept of wireless transmission of electricity. His device is now known as the Tesla coil. Its function was to transmit electricity from a stationary position to a stationary object.

The recent research by Prof. Shanhui Fan at Stanford has added the ability to transmit electricity to a moving object. His team uses a new principle of operation relying on a “feedback resistor and voltage amplifier system that automatically detects where the energy should be pointing”.

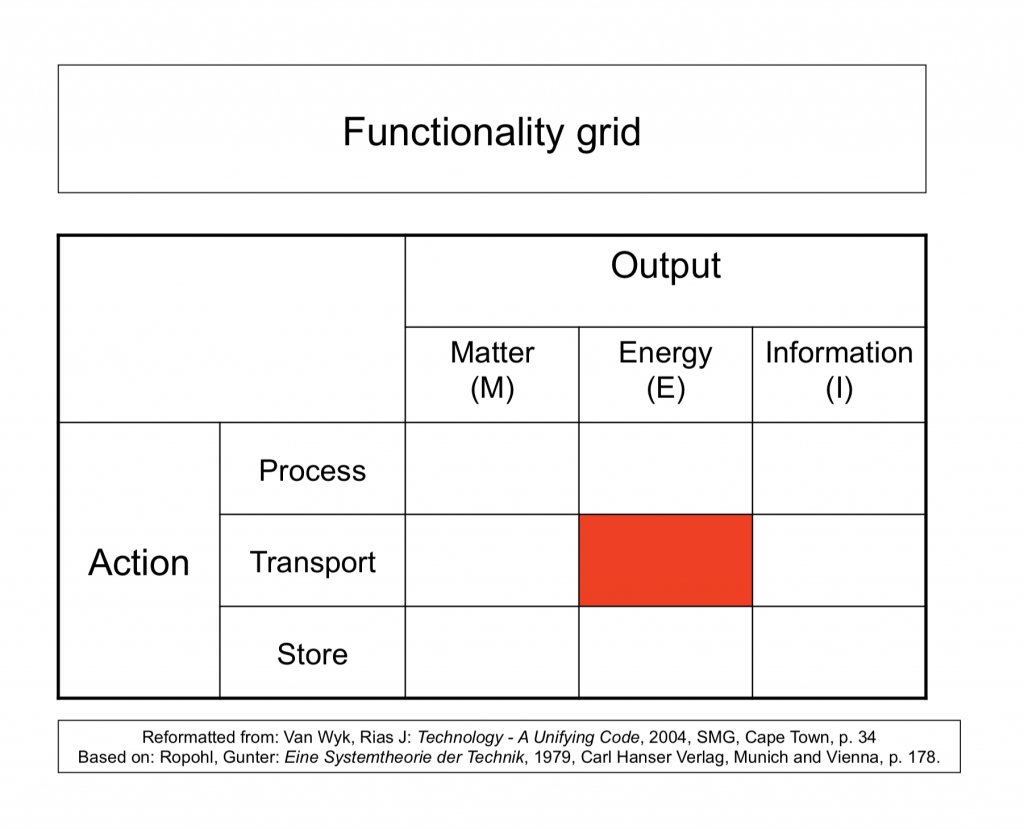

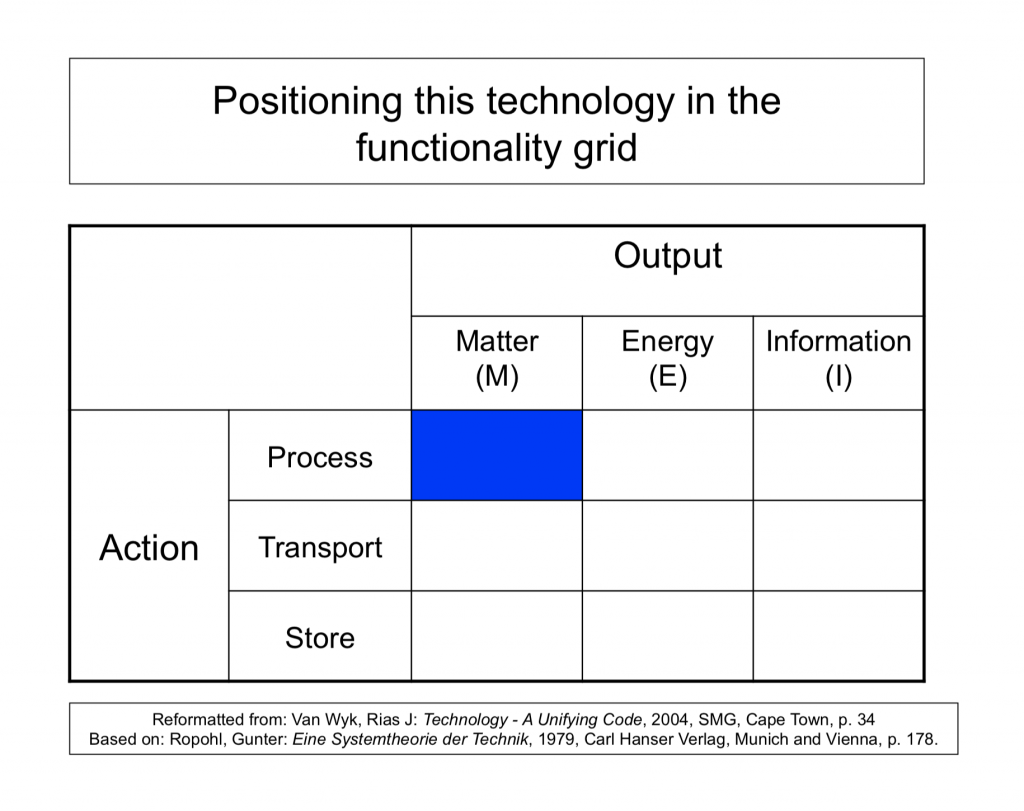

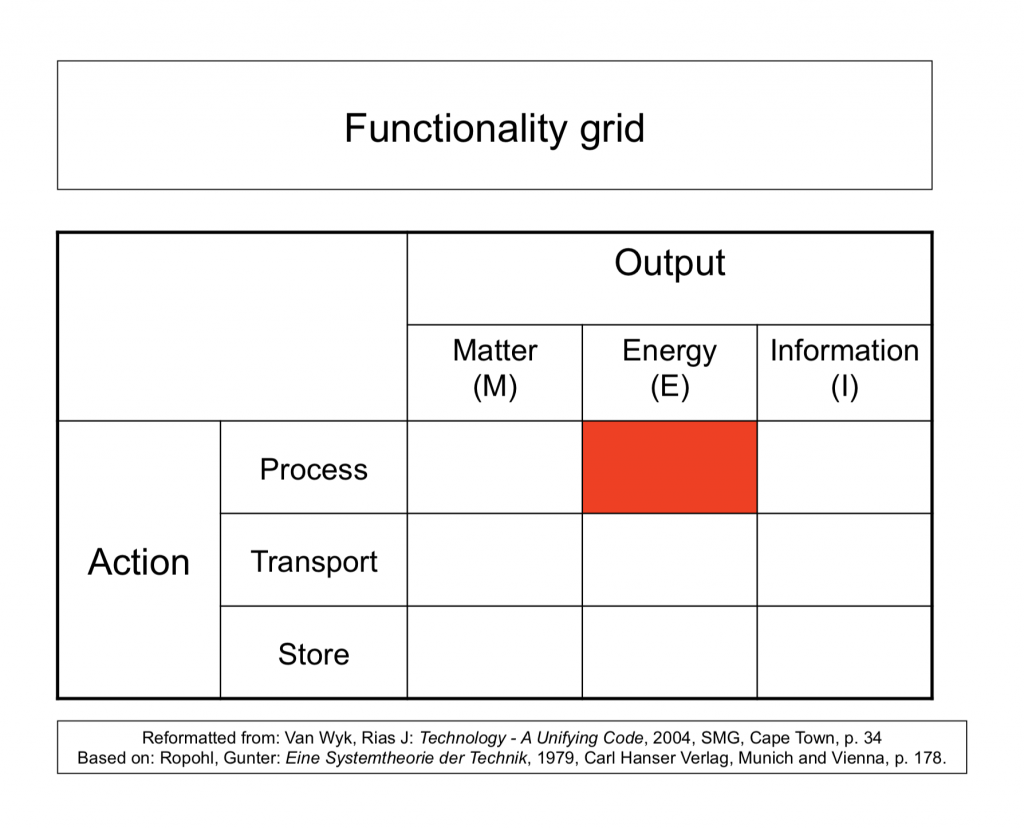

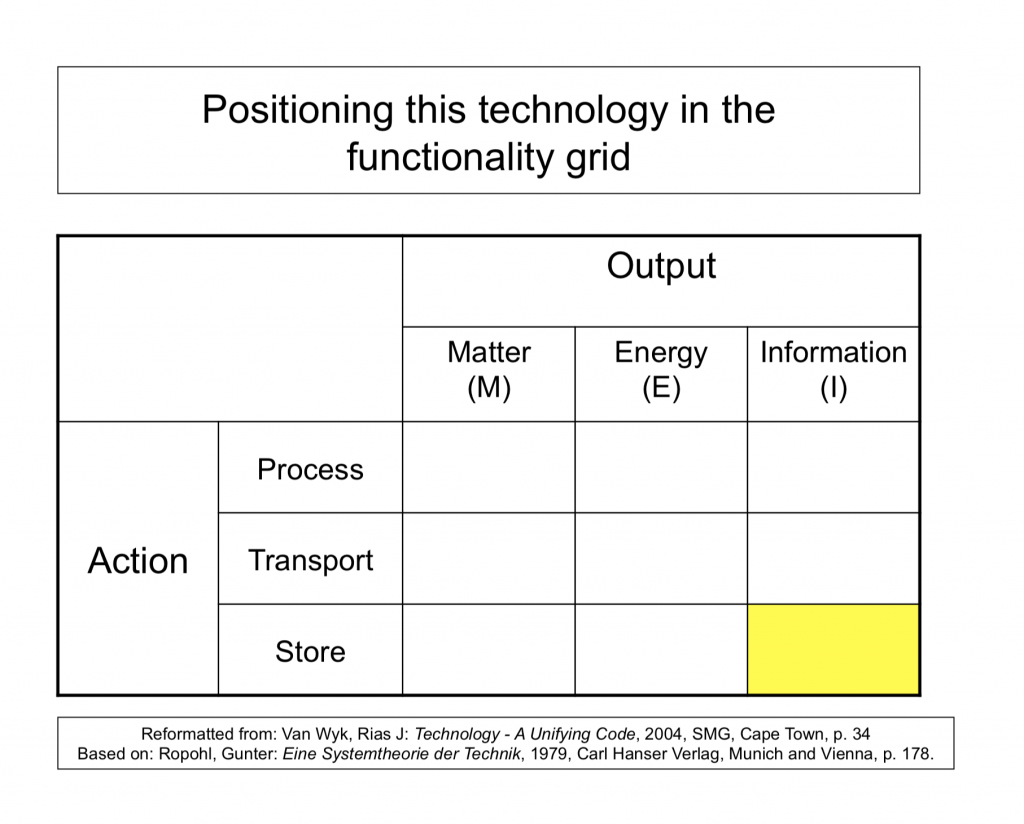

The effect of this innovation is to improve the functionality of Transport-Energy. Its position in the techno-sphere is indicated on the Functionality Grid. (See illustration below).

An appropriate functional performance metric is energy transmitted x distance covered per unit of energy required. At present this is about half of that which would be needed to recharge a moving electric vehicle.

The technology readiness level is said to be TRL 4 on a scale of 1-9, i.e. “Technology validated in lab”.

Technical terminology is covered in: Van Wyk, Rias, (2017) Technology: Its Fundamental Nature, Beau Bassin, Mauritius, LAP LAMBERT Academic Publishing, (http://amzn.to/2Avsk3r)

For descriptions of:

- Technology Landmark; pp. 83-84, Diagram 11.1, Stage 3

- Principle of operation; p. 20

- Functionality; pp. 24-25

- OmegaMap; pp. 92-93

- Functionality Grid; pp. 29-32

- Technology readiness levels; pp. 22-23