Regenerative battery charging is regarded as a TechnologyLandmark for use in an OmegaMap.

The information presented here is based on an article; “The World’s Largest Electric Vehicle Is a Dump Truck” written by Courtney Linder and published in Popular Mechanics, August 21, 2019.

The locus of innovation is a new Principle of Operation. Earlier principles of operation required an external energy source to charge the battery, in this case the device uses an internal regenerative charging principle. The truck is used to haul material from a mountainside in Switzerland and to transport it to a cement factory. The truck weighs 45 tons empty. When it is filled it weighs 65 tons. It then descends a gradient of 13 percent and employs a regenerative braking system to refill the battery.

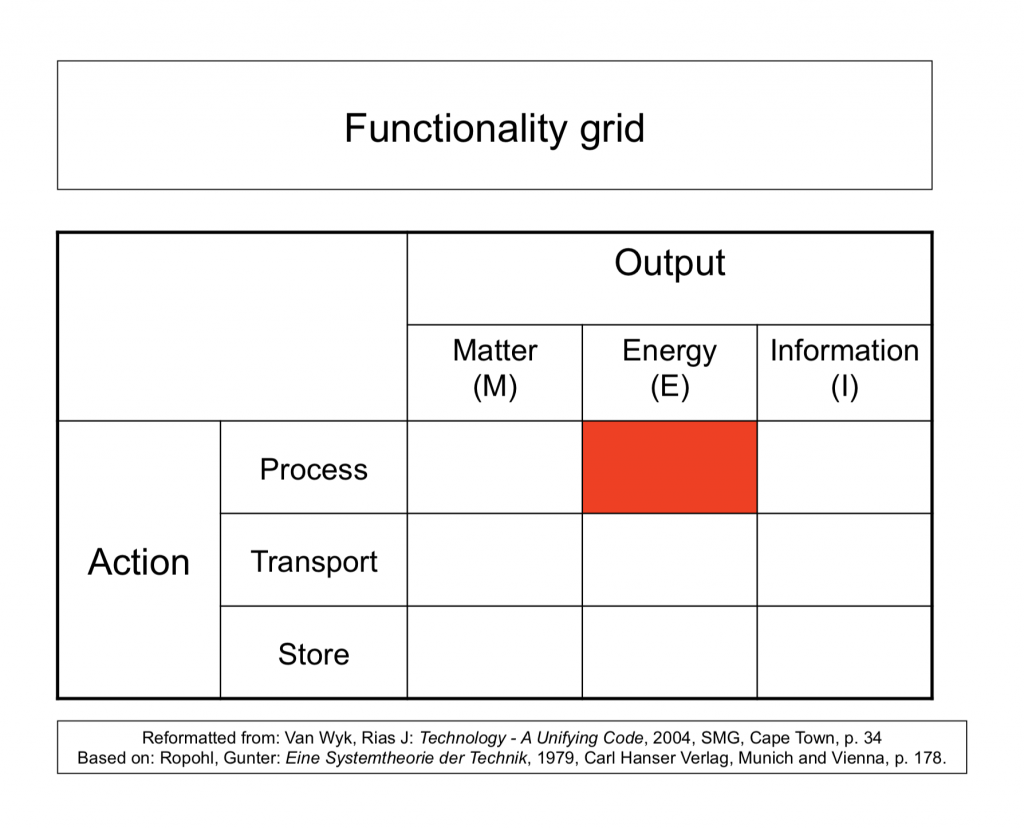

The effect of this innovation is to improve the Functionality : Process-Energy. Its position is indicated on the Functionality Grid. (See diagram below).

The dominant Functional Performance Metric is an increase in the ratio; energy output to external energy input. As the external energy requirement is almost zero, the functional performance metric tends to infinity.

The Technology readiness level on a scale of 1 to 9 is estimated at TRL 7: i.e., “System prototype demonstration in operational environment”.

Technical terminology is covered in: Van Wyk, Rias, (2017) Technology: Its Fundamental Nature, Beau Bassin, Mauritius, LAP LAMBERT Academic Publishing, (http://amzn.to/2Avsk3r)

For descriptions of:

- Technology Landmark; pp. 83-84, Diagram 11.1, Stage 3

- Principle of operation; p. 20

- Functionality; pp. 24-25

- OmegaMap; pp. 92-93

- Functionality Grid; pp. 29-32

- Technology readiness levels; pp. 22-23